(PDF)

The Customer

A world-renowned technology company that provides digital imaging sensors, control instrumentation, test and measurement equipment, and defense and satellite subsystems to markets requiring the highest product reliability possible.

The Objective

To accurately, reliably, and quickly fill battery lids with the proper mixture of 2K epoxy in the shortest time possible.

Before Techcon

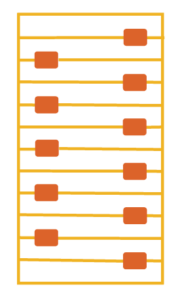

The customer was potting battery lids that required filling an intricate pattern of narrow channels and larger chambers with two-part epoxy.

The customer was potting battery lids that required filling an intricate pattern of narrow channels and larger chambers with two-part epoxy.

They were achieving an excellent throughput of approximately 30 seconds per lid by having operators dispense the epoxy manually.

BUT, dispensing epoxy by hand into the maze of channels was:

- Wasting costly material due to overfilling and inaccurate dispensing

- Creating excessive cleanup work, requiring labor be dedicated to cleaning soiled lids before the epoxy set (or discarding them altogether)

The Challenge: Configure a system that would measure, mix, and dispense 2K epoxy so quickly and so accurately, it would save the customer money (even after the investment in the system)

The customer and the Techcon Team determined that if the Techcon system could accurately pot each battery lid, with no waste or cleanup required, in 3.5 minutes, the customer would make the switch.

Surely, you can imagine how the story ends…

Equipment Used

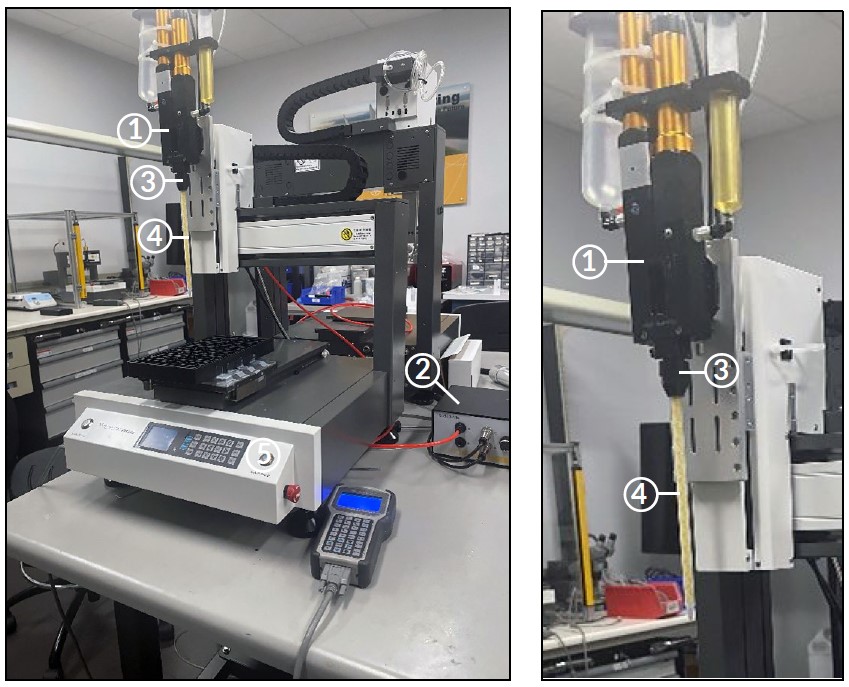

| # | Part Number | Description | Doc |

| 1 | TS8200D-5400 | Micro Meter-Mix 2K Dispensing System, 500 x 400 | TDS |

| 2 | TS580D-MM | Smart Controller for Micro-Meter Mix | TDS |

| 3 | 8200D-000-009 | Nozzle Adaptor for Large Mixing Nozzle | |

| 4 | TMS08-32T | Mixer Nozzle, 8 mm x 287 mm, 32 Elements | TDS |

| 5 | TSR2302 | 3-Axis Dispensing Robot, 300 mm x 300 mm | TDS |

Techcon’s Solution

DISPENSE PATTERN & TIME: Several dispensing patterns were programmed into the TSR2302 Benchtop Dispensing Robot and tested. Techcon was able to ensure the best fill (> 90%) for the battery cover while meeting the target time of 3 minutes and 30 seconds. The robot was programmed to fill the channels following the pattern of the lid, stopping to fill the cavities along the path. The outermost channels (top and bottom) required a slower robot speed to ensure enough material was dispensed to fill them completely, as the robot speed determines the amount of material dispensed into the channels.

MIX: A larger Static Mixing Nozzle (TMS08-32T) was used for this validation process. The larger nozzle requires a nozzle adapter to account for the bell nozzle, but it adequately mixed the epoxy and resin. Despite the larger orifice of the nozzle, it did not change the time required to fill the battery lid as it did not impact the flow rate.

MATERIAL DISPENSING: The material was dispensed using the Techon TS8200-D Micro-Meter Mix, our high-precision 2K dispensing system. Micro-Meter Mix consists of a pair of progressive cavity (PC) pumps for dispensing accuracy of 2K materials of +/- 1%.

OUTCOME: The Micro-Meter Mix, in combination with the TSR2304 Dispensing Robot, was able to dispense the customer’s 2K epoxy, fulfilling the requirement of

3 min 30 seconds per lid.

Parameters were optimized to achieve quality dispensing for the battery lid pattern provided. The dispensing process achieved optimal filling for the cavities and channels, ensuring consistent repeatability among multiple samples.

About the Techcon Products Used

The TS8200D Series Micro-Meter Mix is a precision volumetric mixing and dispensing system for 2-component material. It comprises two progressive cavity pumps integrated in a fluid manifold connected to the static mixing nozzle. Parts A and B of the material are precisely fed by the progressive cavity pump with the correct ratio into the static mixing nozzle to provide accurate mixing and dispensing output.

The TS8200D Series Micro-Meter Mix is a precision volumetric mixing and dispensing system for 2-component material. It comprises two progressive cavity pumps integrated in a fluid manifold connected to the static mixing nozzle. Parts A and B of the material are precisely fed by the progressive cavity pump with the correct ratio into the static mixing nozzle to provide accurate mixing and dispensing output.

TS580D-MM Smart Controller features an intuitive touchscreen user interface for easy setup and operation. Pump calibration is quick and easy. Dispensing parameters can be quickly dialed in on the touchscreen.

TS580D-MM Smart Controller features an intuitive touchscreen user interface for easy setup and operation. Pump calibration is quick and easy. Dispensing parameters can be quickly dialed in on the touchscreen.

TSR2302 Benchtop Dispensing Robots are easy to program, simple to operate, and compatible with all valve types and controllers.

TSR2302 Benchtop Dispensing Robots are easy to program, simple to operate, and compatible with all valve types and controllers.

Designed and configured specifically for fluid-dispensing applications, Techcon robots provide complete control over fluid placement, from beads, arcs, and circles to repeated timed dots. Programming is simple via Teach Pendant.

TMS08-32T Static Mixing Nozzles produce a consistent mix of two-component materials such as epoxies, silicones, urethanes, and acrylics. They enable a quick and easy connection, a leak-free interface, and no cross-contamination.

TMS08-32T Static Mixing Nozzles produce a consistent mix of two-component materials such as epoxies, silicones, urethanes, and acrylics. They enable a quick and easy connection, a leak-free interface, and no cross-contamination.

Need help overcoming your most challenging applications?

Submit our Application Questionnaire and Techcon will test your materials in our recommended systems and send you our Techcon Validation Report at no charge.

Techcon respects the confidentiality of our customers and prospective customers. That is why we do not name specific companies or show the products we have validated in our Application Papers. For a list of references, contact Techcon.