Techcon’s patented disposable microvalve technology could dramatically reduce the maintenance requirements of conventional permanent rotary valves, while offering better performance at a more economic cost.

All permanent rotary dispense valves suffer from one primary drawback: they rapidly become dirty and clogged during use. This drawback affects all manufacturers who need to dispense abrasive and viscous fluid materials, with precision, at some point during their production processes. In the high-performance sector of the electronics industry, prime examples include adhesives, encapsulants, die attach bonding materials, solder paste and BGA underfill.

As such, permanent rotary dispense valves are invariably troublesome and expensive to use as they must be constantly cleaned to avoid damage and performance degradation. A patented disposable microvalve technology from fluid dispensing specialist Techcon Systems, an OK International company, will completely eliminate such traditional problems.

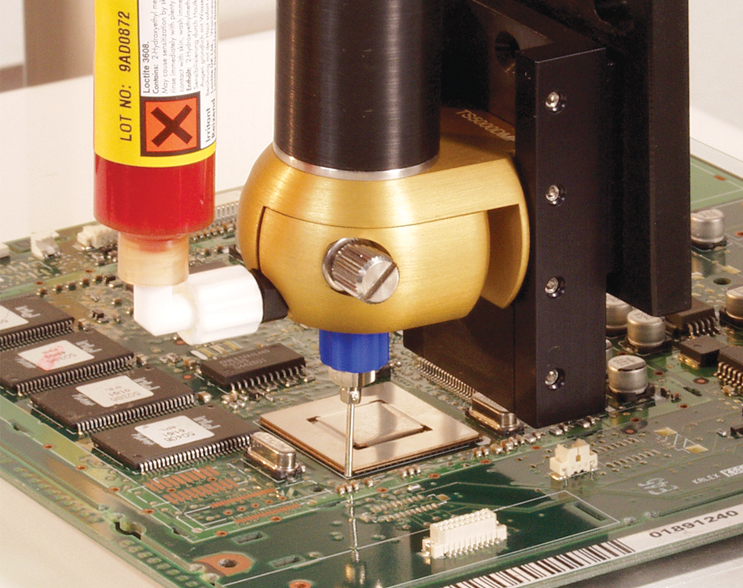

Termed Disposable Material Path (DMP), this microvalve technology provides a consumable aspect to material dispensing processes. This is achieved by exploiting a patented disposable feed screw (auger) arrangement which, thanks to clever engineering, makes the component that is exposed to the dispense material (the feed screw itself) a low-cost disposable item.

Save Time in Cleaning

This microvalve technology is designed to eliminate the need for manufacturers to invest hours of valuable engineering resources cleaning, repairing and maintaining their traditional fluid material dispense valves. Instead it allows them to use a disposable and practically maintenance free high-performance alternative in their production process.

During conventional dispense processes, the fluid materials tend to become squashed down and pressurized to fill up the gaps in the rotary screw feed of the permanent dispense valve. As a result, a rigid, almost solid build-up will quickly amass inside the valve which no material can pass.

This makes cleaning an almost impossibly burdensome task that takes many hours and can easily lead to damage being inflicted upon the valve itself. As a result, manufacturers spend large amounts of money cleaning and repairing the valves, and invariably have to stock more valves than they need to cover the downtime involved while damaged ones are being repaired.

Another problem is that dispense materials used in manufacturing are invariably abrasive and tend to cause the feed screw in conventional rotary valves to become scored over time. This leads to a degradation in dispense accuracy and performance, and can cause premature failure of the valve. As a result, the feed screw has to be replaced or refurbished on a regular basis, which is another source of expensive and time-consuming downtime.

With DMP microvalve technology all these problems are eliminated. As material build-up starts to occur or dispense performance begins to degrade, manufacturers can simply replace the old feed screw with a new one. As a result, the cleaning requirements are dramatically simplified and accelerated and the maintenance burden eliminated. Furthermore, because optimum dispense performance is always maintained, more accurate and reliable dispensing is achieved.

Another major benefit of the DMP microvalve technology is that downtime associated with having damaged conventional valves repaired is also eliminated, along with the need for valve refurbishment. The useable lifetime of the DMP valve is also extended due to less material build-up wear on its component parts.

These huge process and economic advantages mean that this microvalve technology is suited to an enormous range of industries that dispense fluid materials to a high degree of accuracy.

In final assembly, for instance, many products need to be sealed electromechanically by using a suitable bonding material. One major inkjet refill cartridge manufacturer that needed to bond and encapsulate a flexible circuit to their cartridges, however, found that switching to a DMP microvalve halved its valve maintenance costs while eliminating all of its traditional cleaning and repair problems.

This manufacturer discovered that the DMP microvalve’s disposable screw feeds paid for themselves within a week and its line failure rate fell ten times from an original 2% to just 0.2%.

In construction, the DMP microvalves are made completely of ultra-high grade Delrin plastic including their 8in pitch disposable feed screws. They are driven by a 6-watt DC motor and capable of depositing fluid dispense material in small dots down to 0.254mm (0.010″) in diameter at rates of five or more per second, and, or, as a continuous bead in widths that range from 0.254mm (0.010″) to 2.54mm (0.100″) in diameter at rates of up to 101.60mm (4″) per second.

The precision accuracy Delrin moldings also mean that the head of the DMP feed screw and valve housing are allowed to free float, and the auger mechanism will always mesh and interlock perfectly together. As a result, the disposable feed screw is highly interchangeable with no performance differences between one screw and the next. Furthermore, the Delrin plastics also ensure that DMP microvalves offer a fluid material type compatibility that is way beyond that achievable with conventional metallic valves (especially magnetic ferro-fluids).

To make valve replacement exceptionally easy, the DMP microvalves feature a hinged doorway in the front for easy access. This means fitting a new auger screw feed demands no bolting as it can simply be slotted into place within seconds while a production line is still in operation.

DMP microvalve technology offers all the benefits of a traditional rotary valve, while offering exceptional ease of maintenance with zero cleaning, repair and refurbishment requirements. At the same time, the consumable nature of the DMP valves means that they deliver a far higher level of consistent dispense performance and are a dramatically more cost-effective dispense solution.