Manufacturing in America and the world has come a long way from the days when human workers were depended upon to bring quality and fast production. While our country did well in creating products that stood the test of time, mistakes were always inevitable. The cost of paying manufacturers to the salary levels they demand is also more challenging than in past decades.

Fifty years ago, many manufacturers perhaps feared they’d lose their jobs to robotics someday. We’re currently in the middle of a wondrous age of robotic manufacturing, though they’re gradually complementing jobs rather than taking them away.

Take a look at what lies ahead in using robots for dispensing manufacturing and their broad impact.

How Many Robots Are Being Used in Manufacturing Now?

CBS News recently showed the auto industry presently uses the most robots, and that’s likely unsurprising to most of you. While most use of robots in manufacturing is occurring in the central and eastern portions of the U.S., almost every manufacturing industry uses them to some degree.

To prove the point of robots complementing jobs, the above CBS report indicates many auto industry manufacturers started upping their hiring after using more robotics. Without using robotics and increasing their profits, it’s very likely they wouldn’t have hired more human workers.

This proves humans can easily work with robots. The latter is simply taking on manual tasks considered too demanding for those with a beating heart.

While the above map is more in tune with robots creating cars, the future looks bright in robots helping in manufacturing facilities across the world.

Opening Up More Jobs

For added examples in how robots could create more manufacturing jobs, you have to look outside the U.S. In Germany, they’re already using three times more robots in manufacturing than America does. Yet, they still hire the same amount of human workers as they did before.

The reason this occurs is because robots are taking on all repetitive assembly tasks while allowing manufacturers to open other job opportunities for real people.

Converging intelligence from robots and humans is expected to increase speed, flexibility, and efficiency to keep up with 21st century demands.

So what kind of mundane tasks are we seeing robots take on to avoid critical errors?

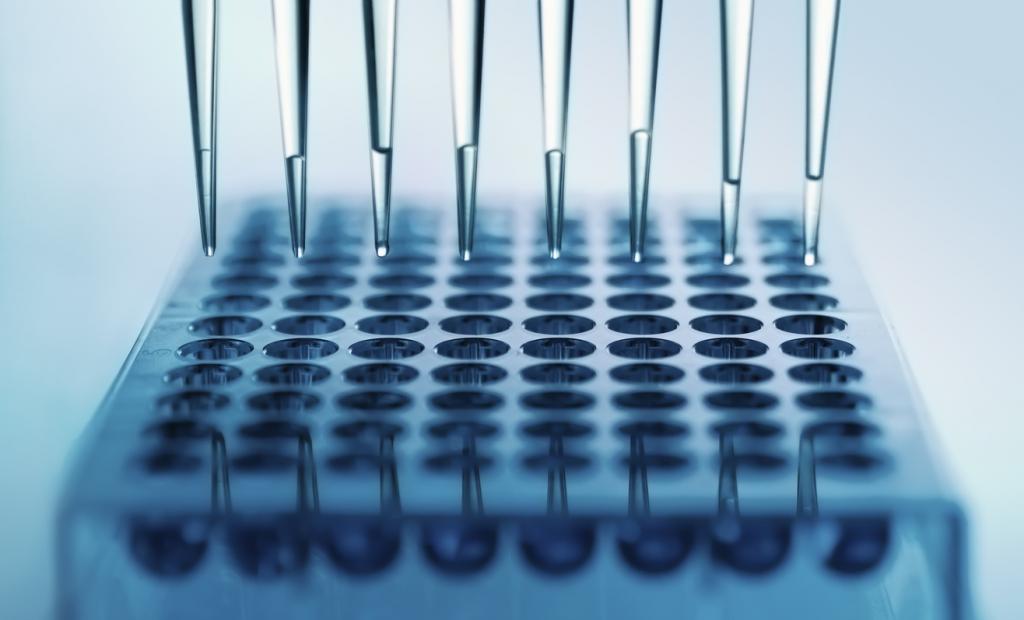

Aiding in Manual Dispensing

Many manufacturing analysts note manual dispensing of adhesives and fluids is one of the most exacting tasks in this industry. Human beings used to do this type of work, sometimes leading to major mistakes. A lot of success depended upon how experienced and skilled the workers were.

With competitive tasks often leading to injury (and even boredom) without proper breaks, robotics has become a major gift to handle these jobs.

Manual dispensing in general is now being taken over by semi-automated robotic dispensing machinery.

If this sounds daunting in capital investment, consider the ROI is exponential. Statistics show ROI from using robots in manufacturing often helps achieve a significant profit within two years. All of this comes from increasing output and quality, not including saving on energy bills since robots don’t require lighting or climate control.

The Role of Industrial Internet of Things

No doubt you hear a lot about The Internet of Things, but Industrial Internet of Things (IIoT) is becoming better known in manufacturing. In fact, you can expect IIoT to become a standard by the coming decade.

It works much the same way as general IoT, except you’re connecting multiple devices within numerous manufacturing facilities. What this does is do more than just increase production rates across multiple manufacturing locations. It also brings a domino effect in bringing more data and in eliminating training time.

As Robotics.org notes, robots are already inherently connected. Making them become a part of an IoT network creates a chance to optimize like never before.

In the realm of data, IoT is going to offer recorded metrics on their own performance to eliminate manual maintenance checks. Gleaning data as a whole from these devices is going to help you make smarter business decisions on what dispensing machines need fixing or replacing.

Most importantly, it’s going to allow each manufacturing robot to communicate with one another. One connected device could train another connected device how to do a particular task, bringing a whole other level of training like you’ve never seen.

The Role of Machine Vision

If robots can communicate with one another and handle more complex manual tasks, they also have eyes of their own.

The current type of machine vision in use uses a marking system (or reference images) on a small section of a work piece. When a small camera captures this image, it’s stored in a database for easy reference.

Automated systems are good examples in how machine vision works today. These machines use software to bring integrated vision and laser height sending capabilities.

One benefit to using this software is it gives you an on-screen preview so you know exactly what dispensing area to cover. Through the laser height sensor, you’ll also be able to check for surface height variations.

Working with robotic technology like this allows for more precise and accurate dispensing. In other words, the future of dispensing robotics is already here.

Techcon is another popular dispensing automated system, making the TSR2000 Series Smart Dispensing Robots a new robotics leader.

What makes Techcon such a standout is it’s easily compatible with all valve types and controllers. This isn’t always the case with many other dispensing robotic systems.

The vision systems are superior and allow you to automatically correct part misalignment for true precision dispensing. It also has a pattern recognition feature to help you shorten programming times. It has a laser height sensor so you bring more accuracy to surface height changes. Laser technology additionally helps with part variations.

These machines even come with “Smart Kits”, giving you various options based on needs. Some come with a touch screen system for easier usage. Other versions come with a vision kit.

Making Robotics Affordable

Despite an assured ROI after investing in robotics, some manufacturing facilities still balk on buying them based on the initial cost. Things are changing now, and a lot of it has to do with the affordability of consumer electronics.

Many technologies thought out of reach are now being used in everyday households. As a result, it’s giving those in the manufacturing sector more incentive to acquire this technology. Some of it comes directly from things as common as Microsoft’s Xbox 360.

In the above device, machine learning is becoming more common, especially in learning about human movement. By hacking into an Xbox 360, some manufacturing facilities have already realized the potential in using robots without essentially “teaching” them anything first.

Visit us at OK International to learn about our two divisions: Metcal for our soldering product, and Techcon for our fluid distribution products.