Today’s adhesive dispensing products deliver an unprecedented level of accuracy and performance. As manufacturers introduce product enhancements and energy-efficient technology in an effort to maintain a competitive edge, engineers and technicians are now able to complete projects at an unprecedented rate. Whether you work in the aerospace arena or the medical equipment industry, you can likely appreciate the technological enhancements and product options offered by today’s dispensers. Below are the top ten advantages of adhesive dispensing products.

1) Fully digital products promote production speed

Manufacturers and consumers are now able to obtain fully digital adhesive dispensing devices at an affordable price. In contrast to manually operated dispensers, digital products can help expedite production in the following ways:

- Adhesives are applied faster

- Operators are able to perform their job for longer time periods

- Manufacturers are able to meet or exceed client demands more effectively

- Operators are able to apply adhesive with less effort

2) Eco-friendly technology helps preserve resources

With 81% of consumers expressing a willingness to make personal sacrifices to preserve our environment, manufacturers of adhesive dispensers have responded by designing products that help control waste and conserve energy. Some of the most eco-friendly design elements include the following:

- Piston/plunger with precision wiper edge design helps eliminate residue on the syringe/cartridge wall

- Environmentally conscious users can choose manually operated devices to minimize energy usage

- A small footprint minimizes use of materials and human resources

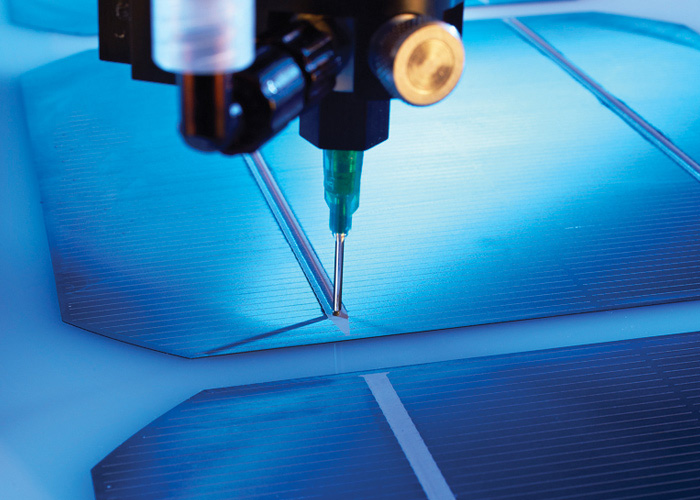

3) Programmable designs bolster efficiency and accuracy

“Increase in need for precision and accuracy coupled with an urge to use highly configured adhesive dispensing equipment is expected to propel the machine mounted and rotary glue dispenser equipment.”

– Transparency Market Research

Standardization and accuracy are two of the most critical goals to pursue in the realms of engineering and manufacturing. The latest cutting-edge adhesive dispensing products enable manufacturers to achieve these two goals while also increasing efficiency. Dispensers with programmable designs bolster productivity by offering these features:

- Some models can be programmed to facilitate up to 10 individual, sequenced or varied shots

- Repeatability is improved through programmability and digital controls

- Reproduction of beads is achieved quickly and accurately

4) Key industry certifications and warranties facilitate compliance

Today’s top adhesive dispensing products meet the strictest regulatory requirements and possess key industry approvals. In addition to being sold with a warranty, they bear CE, TUV-GS, and NRTL approval stamps, enabling users to prosper during audits and quality control inspections.

5) Lightweight, portable products are easy to ship and transport

Gone are the days of heavy, cumbersome adhesive dispensers. Current model dispensers are smaller and lighter weight than their predecessors, making it easy and affordable to transport them from one work locale to another. With some dispensers weighing less than three pounds, they can be carried in one hand or packed in a travel bag for easy transport.

6) Designed for general applications and low viscosity applications

Manufacturers vary greatly in terms of the types of adhesives they use to prepare products. The ability to select an adhesive dispenser with the proper operating pressure is essential to achieving sound product quality. Current adhesive dispensers are often available in the following two versions:

- 0 to 100 psi for use with general product applications

- 0 to 15 psi for use with low viscosity applications

7) Universal power supplies encourage global expansion

In years past, many adhesive dispensers were made without this valuable component. They were designed to operate in either 100-120 volt countries or 220-240 volt countries. A universal power supply enables manufacturers with operations across the globe to standardize their equipment and manufacturing processes.

8) Products are available in power and manual versions

While today’s adhesive dispensers are far more sophisticated than yesterday’s models, there are still some instances that call for a manual dispenser. Here are some examples of situations that warrant a manually operated adhesive dispenser:

- A manufacturer is seeking the most cost-effective dispenser possible

- Manufacturing is completed in an area that is prone to power outages

- Adhesives are being applied in a remote setting where access to power is extremely limited

9) Conveniently packaged with all accessories

Like most consumers, today’s engineers and technicians appreciate convenience. Many current model adhesive dispensing products are packaged with convenience in mind, enabling users to have immediate access to key accessories such as the following:

- Foot switches

- Air hoses

- Sample tips

- Syringe barrels

10) An intuitive design shortens the learning curve

Introducing new tools and products to a manufacturing team is not always a smooth process. There may even be resistance to learning how to use new tools or technologies, even if they have a stellar reputation. Fortunately, the latest adhesive dispensing tools and options have an intuitive design that shortens the learning curve and helps manufacturers resume production quickly after introducing them to employees.

Remembering the Role of the Operator

“Adhesive dispensing is a delicate and highly sensitive process and therefore calls for trained and experienced operators. The operators should be able to predict problems and adjust the process accordingly to guarantee a good dispensing quality. Things like: shape of dots, position of adhesive dots and volume should be controlled regularly.”

– Epoxy Technology

Even the latest cutting-edge technology does not erase the need for a highly trained, experienced operator. As you invest in new adhesive dispensing products, it is important to ensure that operators, engineers, and other team members are thoroughly trained on each new product.

How can you find the best adhesive dispensing products?

Clearly, adhesive dispensing products have evolved greatly over the past decade. Despite these product enhancements, not all adhesive dispensing devices are created equal. Securing top-notch products to meet your specific needs is best achieved with the guidance of an industry expert. By seeking the expertise of a leader in the adhesive dispensing industry, you can help ensure that you invest in products that are as accurate as they are durable.