5 min. read

Electrically conductive adhesives (ECA) continue to grow in use throughout the military and defense, aerospace and medical manufacturing industries for their electrical and thermal conductivity and their versatility as a bonding material. Let’s take a look at ECAs, the reasons to use ECAs, and the advantages of using a jet valve system for their application in electronics manufacturing.

Topics covered:

What Is Electrically Conductive Adhesive?

What are ECAs Made Of?

Key Reasons to Use Conductive Adhesives

What Industries Commonly Use ECAs?

Methods of Applying Electrically Conductive Adhesives

The Advantages of Jet Dispensing Electrically Conductive Adhesive

Why Choose a Jet Valve System Over a Stencil Printing System?

What Is Electrically Conductive Adhesive?

Electrically conductive adhesives (ECAs) (sometimes referred to as “conductive adhesives”) are exactly what they sound like: glues, adhesives, and epoxies that not only bond surfaces together but also conduct electrical current.

What Are ECAs Made Of?

ECAs are made of a solid, electrically-conductive filler and an adhesive base material.

Fillers are metal or metal-coated particles, commonly made of silver or gold. The soft metal flakes offer good particle-to-particle conductivity by clumping during the curing process as the liquid adhesive shrinks.

The most common adhesives are:

- Epoxy – a polymerized mixture of two compounds, a resin and a hardener

- Silicone – a water-resistant polymer made primarily of silica, a form of quartz sand.

- Acrylate – Also referred to as methyl methacrylate or MMA, a resin-based, two-component adhesive. We’ll talk about 2-part materials in our next blog post – Stay tuned!

The combination of the conductive fillers and the adhesive creates a versatile and flexible material for many vital applications.

Key Reasons to Use Conductive Adhesives

- Applications that require strong bonding, superior conductivity, thermal conductivity, and heat dissipation.

- Applications where both flexibility and conductivity are required.

- As an alternative to solder, when the heat required for soldering would damage temperature-sensitive electronic components.

- When strong interconnections between components and PCBs are required for reliable performance.

- For assemblies with a high risk of mechanical or thermal cracking.

- For dependable fine-pitch and flip-chip interconnections.

- Surface mount, die-attach, and gasketing applications.

- Mounting small components to interconnect substrates (including flexible substrates).

- Where there is a high CTE (coefficient of thermal expansion) mismatch between components and substrates.

What Industries Commonly Use ECAs?

Electronically conductive adhesives are commonly used in manufacturing assemblies for:

- Aerospace

- Automotive

- Medical devices

- Telecommunications equipment

- Consumer electronics

Examples of specific uses of ECAs include:

- Radar and camera systems

- LiDAR (Light Detection and Ranging) aka “laser scanning” or “3D scanning” assemblies

- ADAS (Advanced Driver-Assistance System) data modules

- EMI/RFI shielding (Electromagnetic Interference/Radio Frequency Interference)

Methods of Applying Electrically Conductive Adhesives

These are the three most common methods of applying ECA onto an assembly or substrate, each with its own pros and cons:

- Screen Printing/Stencil Printing

- Contact Dispensing

- Jetting

1. Screen Printing/Stencil Printing

Screen printing or stencil printing is much like using a stencil to paint a shape onto a flat surface. Conductive adhesives are applied to substrates or printed writing boards through a pre-made template cut to precise patterns. Because the ECA is applied to the entire board in a matter of seconds, screen printing is a very fast process.

Screen printing enables the production of large numbers of very complex printed assemblies like printed circuit boards, printed wiring boards, and printed circuit assemblies very quickly.

The Advantages of Screen Printing ECAs

- Screen printing equipment can be cheaper than dispensing equipment

- May require fewer machines than would be needed for dispensing

- Very fast process, only takes 10 – 15 seconds per board, 4 – 6 PCBs per minute

The Disadvantages of Screen Printing ECAs

- This method is only possible on flat, empty boards

- Requires costly cleaning every 2 – 3 hours

- The required cleaning chemicals can be hazardous

- Because of toxic fumes, stencil printing requires the installation of exhaust fans and other safety equipment

- Any change in the product design results in the need for new, costly stencils

- Stencils only last 3 – 4 hours before their performance begins to suffer

- Inconsistent material deposit amounts result in waste and rework

- Changes in material deposit amounts require new stencils since deposit volumes are dictated by the stencil thickness

- Stencils with small holes and narrow shapes often have clogging issues, especially without proper and frequent cleaning

2. Contact Dispensing

In contact dispensing, a dispensing valve or pump, attached to a multi-axis robot, follows a pre-determined pattern, applying the ECA. The dispensing tip or needle is lowered to the target surface until it makes contact (hence, “contact dispensing”), and releases a controlled quantity of material. The process is very accurate and highly repeatable.

Contact dispensing allows for the application of ECA not only on bare boards but on populated and uneven substrates as well.

An excellent example of a contact dispensing system appropriate for ECAs is the Techcon TS8100 Progressive Cavity (PC) Pump, with volumetric accuracy of +/- 1%.

The Advantages of Contact Dispensing ECAs

- Capable of dispensing very small dots and lines very accurately

- Able to dispense on uneven surfaces, into small holes

- Fluid volumes and patterns can be customized and adjusted at any time through the valve’s controller

- Dispense volumes can be set to different levels for each area of the substrate

- Dispensing systems are much easier to clean and maintain than screen printing systems

- No need to create costly stencils for each design

The Disadvantages of Contact Dispensing ECAs

- Contact dispensing systems offer slower output than screen printing systems

3. Jet Dispensing

Jet dispensing is much like contact dispensing but without contact. Instead of being lowered by the robot to touch the substrate, a jet valve glides above the substrate, literally shooting the fluid onto its target. Through pneumatic or piezo-actuated technology, a jet valve can dispense at amazing speeds.

The Advantages of Jet Dispensing Electrically Conductive Adhesive

Jet valves offer many of the advantages of contact dispensing, and more, including:

- Capable of dispensing very small dots and lines very accurately, with shot sizes as small as 0.5 nanoliters

- Able to dispense on uneven surfaces, into small holes, and at angles into hard-to-reach locations. This is not possible with screen printing

- Dispense with volumetric accuracy up to 97%

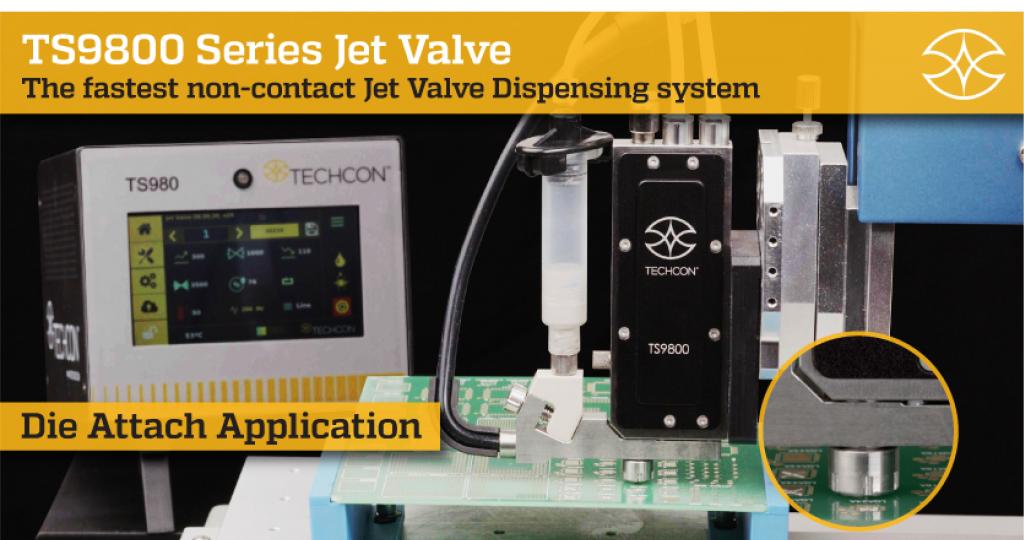

- Very fast dispense speeds up to 1500 Hz continuous, 2000 Hz burst can be achieved with the Techcon TS9800 Jet Valve, the fastest dispensing system available

- Fluid volumes and patterns can be customized and adjusted at any time through the controller

- Dispense volumes can be set to different levels for each area of the substrate

- Jet dispensing systems are much easier to clean and maintain than screen printing systems

- No need to create costly stencils for each design – dispense volumes, rates, and patterns can be set on the valve smart controller and the robot

Explore all Techcon TS9800 Jet Valve Resources

Why Choose a Jet Valve System Over a Stencil Printing System?

At first glance, screen printing may look like the fastest and most cost-effective method of applying electrically conductive adhesives. But when you consider the advantages of jet valves over the many limitations and maintenance issues of screen printing, jet dispensing is clearly the ECA solution for a modern manufacturing operation:

- Very fast dispensing speeds. See the video above. The TS9800 is so fast, we had to slow the video down to 50% speed

- Apply tiny dots and lines without the fear of a clogged stencil

- Able to apply ECAs on flat and uneven surfaces, at angles, and into difficult-to-reach spaces

- Volumetric accuracy of +/- 3% reduces waste and rework

- Dispensing patterns and volumes can be accurately controlled and changed without the need for new, costly stencils, which saves money and expands the versatility of your operation

- Increased throughput since system cleaning is only required at the end of a workday – no time-consuming clean-up every 2 – 3 hours

- No need for additional safety equipment due to harsh cleaning chemicals

- Jet valves can also be used for die attach, chip bonder, underfill, and other applications for added adaptability

If you are considering a jet dispensing system for applying ECAs, contact Techcon to learn more about the TS9800 Jet Valve with piezoelectric technology. Techcon will gladly test your materials with the TS9800 in their labs, to best determine how Jet Valve can improve throughput and reduce waste in your operation.

_ _ _

ABOUT TECHCON: Since 1961, Techcon has provided precision fluid and adhesive dispensing equipment to a range of service industries, including industrial assembly, aerospace, military, material packaging, medical device, and electronics. Techcon products are renowned for their superior accuracy and durability, yielding improved industrial hygiene and enhanced productivity. Backed by our expert engineering team, Techcon, an OK International company, is delivering smarter, cleaner, more durable solutions. For more information, keep browsing Techcon.com.