5 min read

The very simple capillary underfill process is essential to modern manufacturing, and nowhere is it more important than in automotive and aerospace manufacturing, where reliability and safety of the equipment are the most important factors. Underfill protects the finished electronics against damage from impact, moisture, thermal shock, and differences in the coefficient of thermal expansion (CTE) between chip packages and their carriers.

It is estimated that roughly 90% of manufacturers have adopted jet dispensing for their underfill applications, taking advantage of the extreme dispensing speed of a jetting system.

If underfill dispensing speed is such a high priority, why wouldn’t operations make the simple switch to the fastest jet dispensing system available?

TOPICS COVERED

For Outstanding Underfill Application Speeds, Choose a Jet Valve

For The Fastest Underfill Application Speeds, Choose the TS9800 Jet Valve

Underfill Dispensing Video

Jet Valve Purchasing Checklist

For Outstanding Underfill Application Speeds, Choose a Jet Valve

Operations have switched from progressive cavity pumps and auger valves to jet valves for underfill applications largely because jetting is a non-contact dispensing method. To complete a dispensing cycle, a pc pump or auger valve is required to move into position, be lowered to contact the PCBA, dispense the material, be raised, and then repositioned. All this movement on the Z-axis and position/height detection is time-consuming.

Not so with a jet valve. A jet valve moves above the substrate, shooting the underfill material down onto its intended target. By not contacting the PCBA, the jet valve is free to dispense at outstanding speeds, with no risk of damage to the board due to needle crashes.

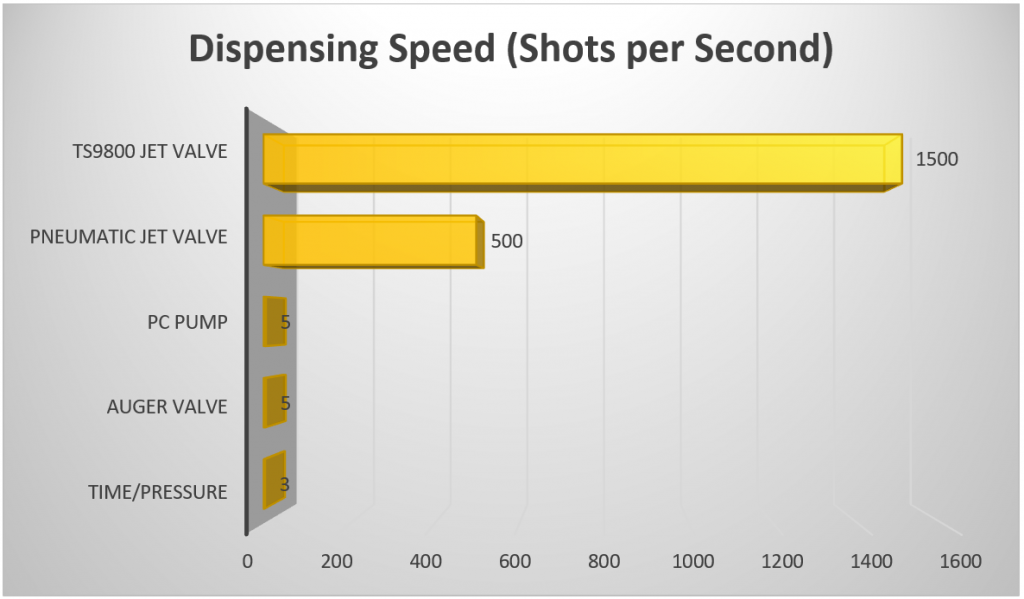

Jet valves average speeds 100 times faster than contact-based pc pumps or auger valve dispensing systems.

If speed (and therefore throughput) is a priority, a jet valve is clearly the dispensing method of choice. But why settle for 100 times the speed of a contact-based system when you can just as easily achieve speeds that are 300 times faster with Techcon TS9800 Series Jet Valve?

For The Fastest Underfill Application Speeds, Choose the TS9800 Jet Valve

The state-of-the-art Techcon TS9800 Series Jet Valve System is blazingly fast, depositing micro shots at up to 1500 Hz continuous, 2000 Hz burst.

The state-of-the-art Techcon TS9800 Series Jet Valve System is blazingly fast, depositing micro shots at up to 1500 Hz continuous, 2000 Hz burst.

This is literally 300x faster than an auger valve, and 3x faster than even a typical pneumatic jet valve, making it the fastest non-contact dispensing system available! (Refer to the Bar Chart Below)

This speed comes from Techcon’s piezo-electric technology. Unlike a more common pneumatic jet valve, the TS9800 does not rely on air pressure to dispense. In Techcon’s piezo jet valve, the fluid starts inside the valve, between the piston and the nozzle. A piezo crystal oscillates up and down, at a high speed, generating kinetic energy. This energy forces the fluid to shoot (“jet”) out of the valve under carefully controlled pressure.

A perfect bead of underfill material is jetted out at the target location, at up to 2,000 times a second!

Techcon Piezo-Actuated Jet Valves Offer Speed and Precision

With all this outstanding dispensing speed, the TS9800 Jet Valve is also able to achieve remarkably small dispensing volumes, jetting deposits as small as 0.5 nanoliters with up to 97% accuracy. This makes underfilling even the smallest components possible at the highest speeds.

Optional Heater Attachment

Because underfill materials need to be protected from fluctuations in temperature, Techcon offers an optional heater for TS9800 Series Jet Valve to ensure underfill materials are always at the proper temperature, maintaining fast and accurate dispensing.

Dial-In the Parameters on The Techcon TS980 Jet Valve Controller for Optimal Results

This speed and versatility are due in part to the power of the Techcon TS980 Controller. Through the controller, operations can fine-tune both material and jetting pressure, to achieve the ideal results for their application.

This speed and versatility are due in part to the power of the Techcon TS980 Controller. Through the controller, operations can fine-tune both material and jetting pressure, to achieve the ideal results for their application.

The Techcon TS980 offers an intuitive touchscreen interface, so parameters can be quickly and easily set and adjusted. Through the standard Ethernet internet connection, the TS980 can be monitored, adjusted, and data recorded from anywhere in the world!

Explore all Jet Valve Resources

Jet Valve Purchasing Checklist

There are several important considerations when purchasing a jet valve system:

Material Dispensing Range

In case your operation deals with more than just underfill materials, it may be important to consider the range of possible materials the system can precisely dispense.

TS9800 Jet Valve can handle viscosities up to 2 million centipoises. Many users can use a single Jet Valve for several applications in the PCB assembly process, from applying low viscosity underfill in navigation systems to dispensing high viscosity die attach epoxies for camera modules or communication equipment.

By using one dispensing system for many applications, operations can reduce parts inventory, streamline training, and greatly enhance productivity.

Evaluate The Level of Support from The Manufacturer

Determining whether a dispensing system is right for an operation is no small feat and should be undertaken with the help of a trusted manufacturer.

Getting the right balance of material pressure, jetting pressure, etc. for your application can be challenging. Techcon provides support to test your underfill material in their labs to ensure the Jet Valve parameters are set up properly and accurately for your operation.

Buy a System, Not Just Equipment

Some operations prefer to purchase from different sources, assembling a system piece-meal in hopes of saving money. This approach will not get you the accuracy and speed you require, resulting in inefficiencies and higher operating costs.

Always opt for the single brand approach, where system pieces are specifically designed to work together as a unit (especially valves and controllers). This leads to superior system performance, but also a one-stop-shop for service and support. Also consider the availability of compatible accessories and equipment to be teamed with the Jet Valves and other dispensing equipment in the operation, like robots and automation equipment, pressure tanks and feeding systems, and dispense tips and syringes.

Purchase From a Manufacturer You Can Depend On

Key to the purchasing process should be whether the manufacturer has experience and knowledge of the circuit board assembly industry, underfill dispensing, and the assembly process in total.

Consider the availability of local repairs or service, lead times, and/or in-person or remote assistance after the sale.

Take Away

When it comes to choosing a dispensing system for automotive and aerospace underfill processes, consider volume precision, dispensing speed, its ability to control material temperature, the possible viscosities dispensed, the level of support from the manufacturer, the system unity, and the integrity of the brand.

If your operation demands the highest speeds possible, with volumetric accuracy and consistency, a piezo-actuated jet valve, like the Techcon TS9800 Series Jet Valve System, is your dispensing solution. Contact Techcon today to see which would best fit into your PCB assembly operation.

![]()

ABOUT TECHCON: Since 1961, Techcon has provided precision fluid and adhesive dispensing equipment to a range of service industries, including industrial assembly, aerospace, military, material packaging, medical device, and electronics. Techcon products are renowned for their superior accuracy and durability, yielding improved industrial hygiene and enhanced productivity. Backed by our expert engineering team, Techcon, an OK International company, is delivering smarter, cleaner, more durable solutions. For more information, keep browsing Techcon.com.